Time of Flight Diffraction (TOFD)

OVERVIEW OF TOFD:

Time of Flight Diffraction (TOFD) is an advanced ultrasonic testing technique used to detect and size cracks and other discontinuities with high accuracy. TOFD is particularly effective in inspecting welded joints and pressure vessels.

HOW DOES IT WORK?

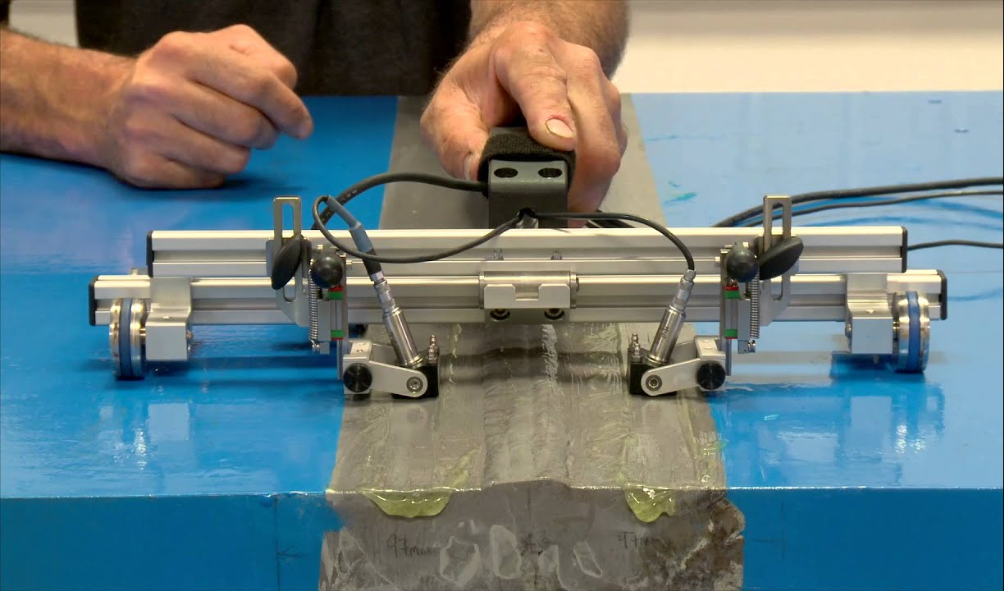

TOFD uses two probes positioned on opposite sides of the weld. One probe emits sound waves, and the other receives the diffracted waves.

When the sound waves encounter a crack or discontinuity, they are diffracted, and the time it takes for these waves to reach the receiving probe is measured.

The data is processed to create an image of the defect, providing accurate sizing and location information.

TOFD is extensively used in industries such as oil and gas, power generation, and manufacturing for inspecting welds, pipelines, and pressure vessels.

- High accuracy in detecting and sizing cracks.

- Can inspect thick materials and detect small defects.

- Fast inspection speed with minimal disruption to operations.

- Requires access to both sides of the weld from cap or root side.

- May require complementary methods for a complete inspection.

have any questions?

Send us an email at [email protected] or call us +61 468 937 996